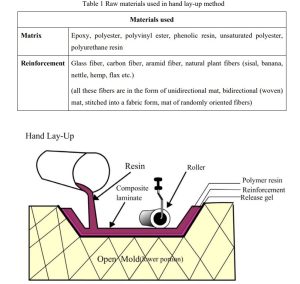

The manual hand lay up

process is one of the main and oldest methods of making composite parts. Handcrafting is the most suitable layer for the production of large parts, and the infrastructure requirements for this method are also minimal. This method is used to make very large parts such as boat hulls, ship decks, swimming pools, tanks, and often for parts that have a simple geometry.

Among the advantages of this method, we can point out the low cost, the possibility of making parts with a high percentage of glass fibers.

The disadvantages of the manual layering method are the quality of the produced piece, the skill of the worker, the waste of materials…

The manual layering process is very simple, first a release wax is used on the surface to prevent the polymer from sticking to the front.

The next step is to apply the gelcoat layer to create high quality and high surface resistance.

(placing a layer of tissue fibers to strengthen the layer of gelcoat that is used)

In the step after applying the resin and placing the required layers…

Waxing is used in the next step to make the piece non-sticky to the mold and easy to separate. A roller is used to smooth the surface to remove bubbles during layering.

The series of resins produced in Alborz Organic Materials Engineering Company with chemistry codes 714, 715, 721, and 730 are economical resins with high quality and mechanical properties suitable for manual layering and spraying.